Developing 3D-Printed Natural Fiber-Based Mixtures

Spring - Summer 23

Fiber-based building mixtures such as light straw clay and hempcrete incorporate vegetable fibers and geological binders, traditionally used as an infill in building construction. As an earth- and bio-based insulative infill method comprised of mostly fiber, heat transfer coefficients are lower than mass materials, making it a compatible insulation material that can meet energy code requirements. In terms of their environmental impacts, fiber-based mixtures that use earth have both embodied and operational environmental advantages: on the embodied phase, fibers sequester carbon. On the operational phase, the juxtaposition of thermal mass and thermal resistivity reduces both heating and cooling energy demand. Furthermore, the material’s ability to perform as a hygroscopic and thus healthier building material shows a future as an alternative construction method.

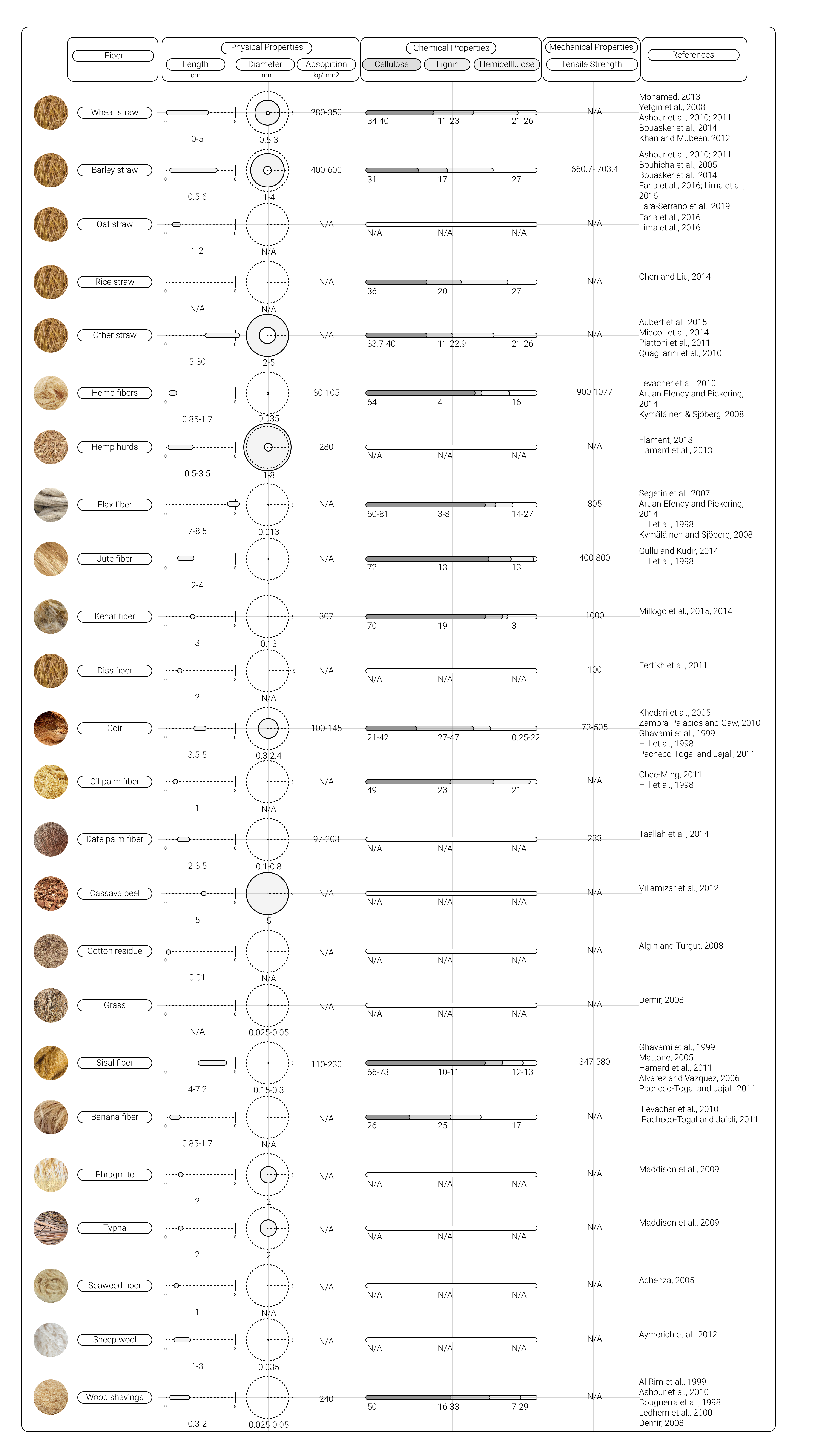

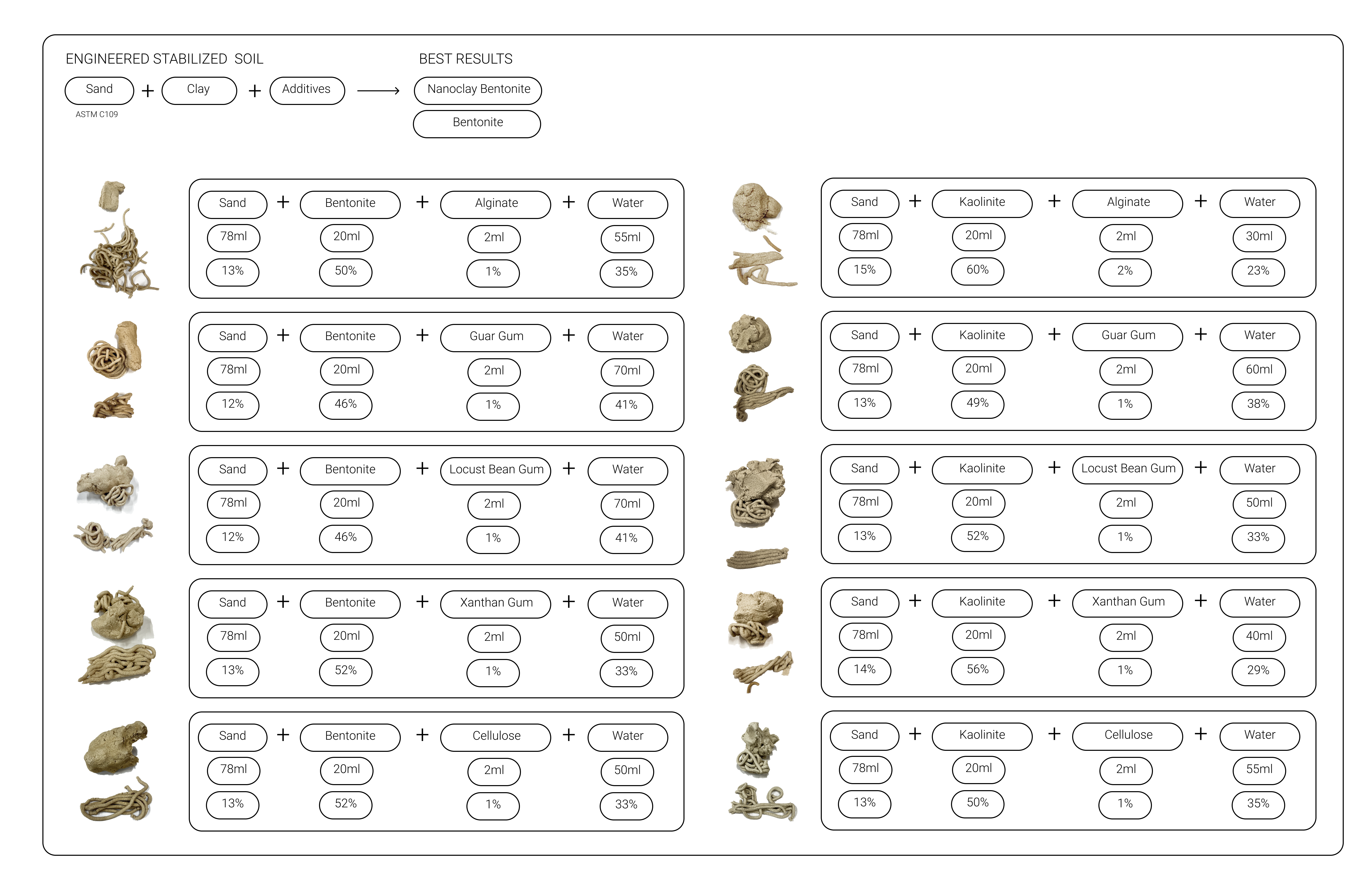

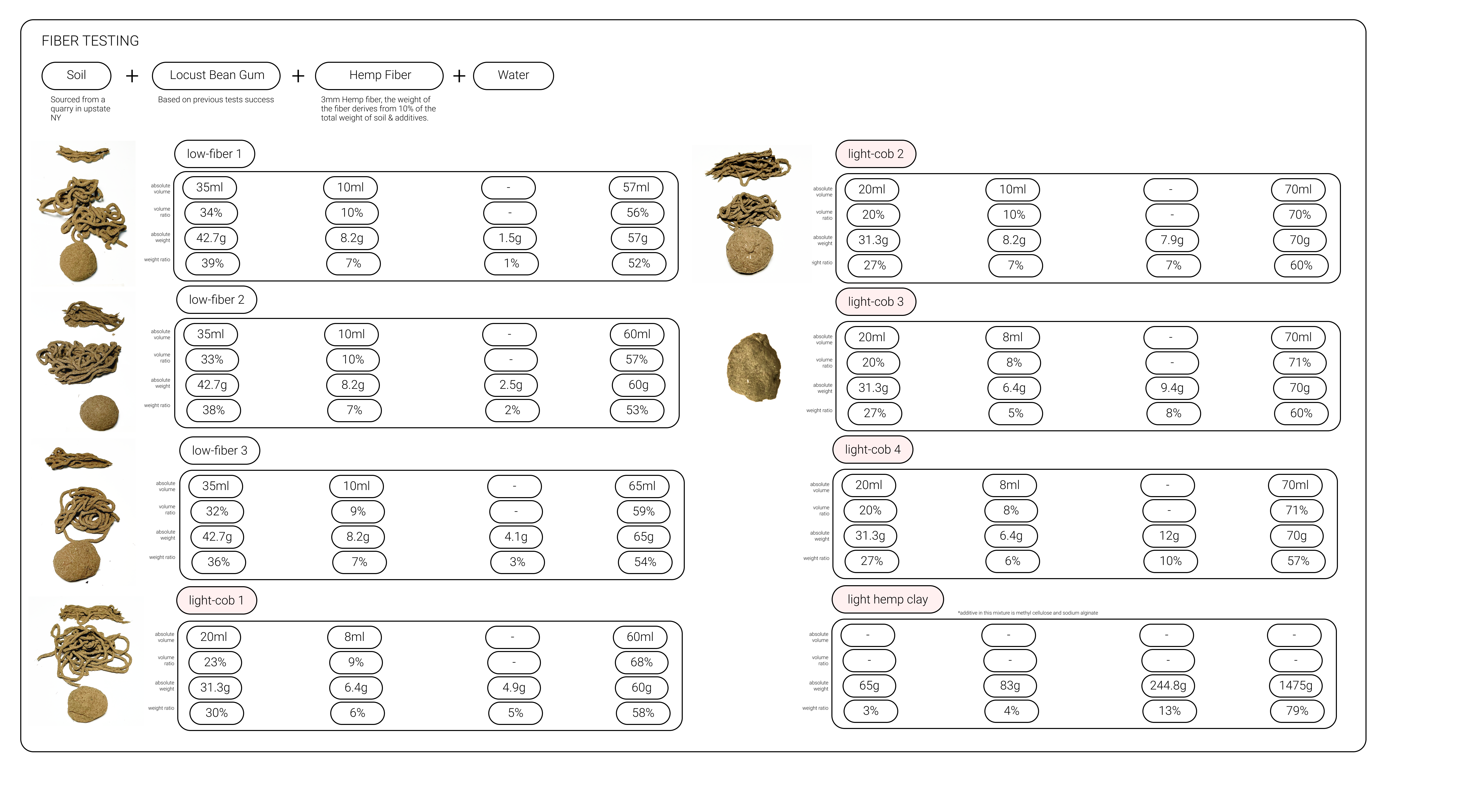

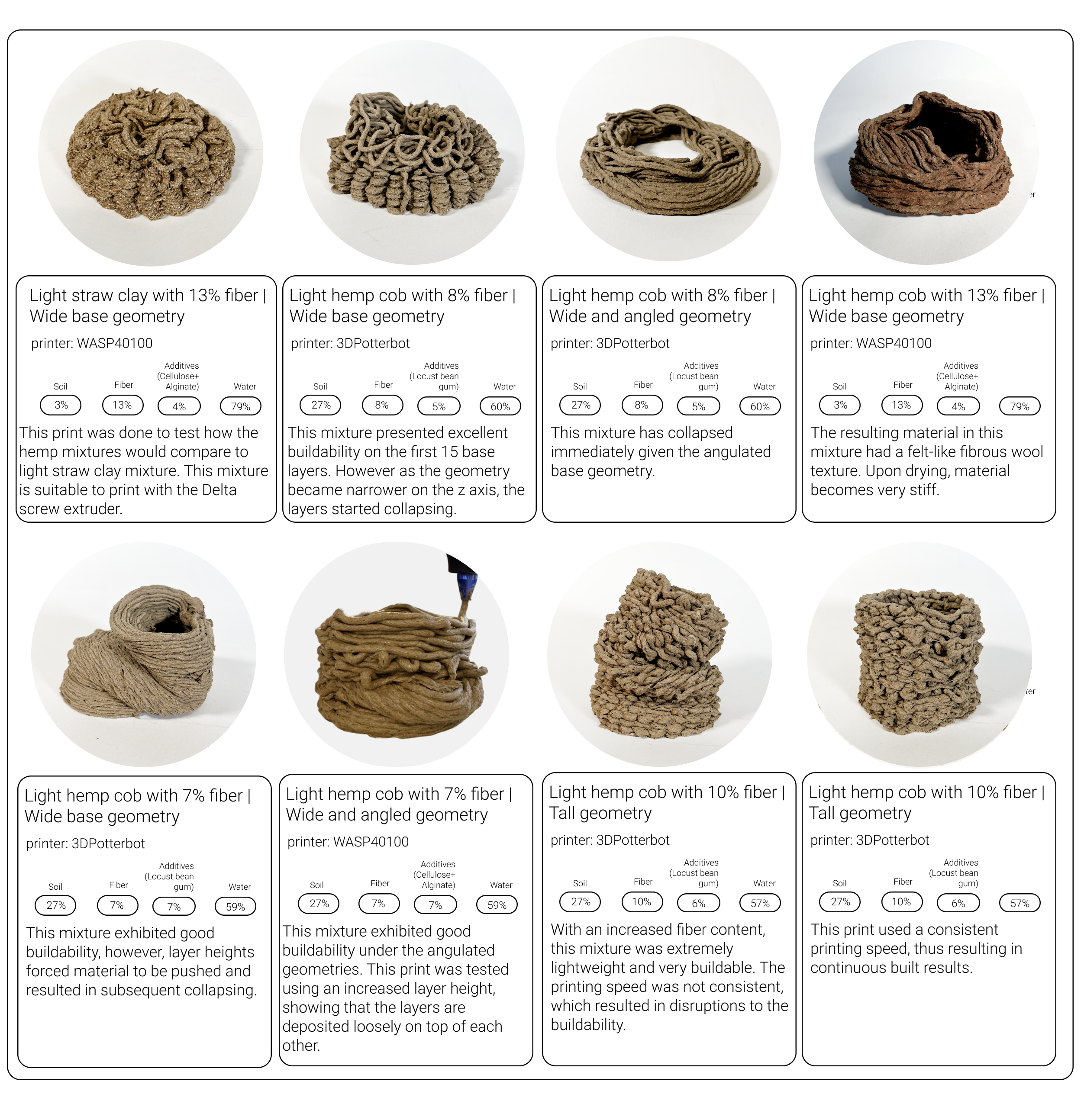

Despite these advantages, the use of fiber-based building materials in digital construction is still missing. In the past few years, 3D-Printing earth based material has gained interest, however, higher contents of fibers in earth mixtures have yet to be fully tested and characterized. This paper concludes a line of ongoing research experiments on fiber-earth compositions for 3D printing technologies using local New York soils, with a range of fibers: straw, flax, hemp, kenaf, and banana leaves, with and without biopolymer additives. Throughout the study, fiber characterization and 3D-printing experiments were conducted, and selected mix designs were used for experimental prints and buckling tests. Additional geometric studies are presented to showcase the lightweightness and structural possibilities of each material.

The significance of this research lies in the development of a novel materiality for parametric modeling and digital fabrication, by increasing carbon storing vegetable fiber content, and creating a range of assembly types: from mass-insulation walls to paper-thin partition assemblage.

Despite these advantages, the use of fiber-based building materials in digital construction is still missing. In the past few years, 3D-Printing earth based material has gained interest, however, higher contents of fibers in earth mixtures have yet to be fully tested and characterized. This paper concludes a line of ongoing research experiments on fiber-earth compositions for 3D printing technologies using local New York soils, with a range of fibers: straw, flax, hemp, kenaf, and banana leaves, with and without biopolymer additives. Throughout the study, fiber characterization and 3D-printing experiments were conducted, and selected mix designs were used for experimental prints and buckling tests. Additional geometric studies are presented to showcase the lightweightness and structural possibilities of each material.

The significance of this research lies in the development of a novel materiality for parametric modeling and digital fabrication, by increasing carbon storing vegetable fiber content, and creating a range of assembly types: from mass-insulation walls to paper-thin partition assemblage.